dataPARC

Empower your enterprise with data-driven decision-making and enhanced troubleshooting capabilities through advanced real-time manufacturing analytics software.

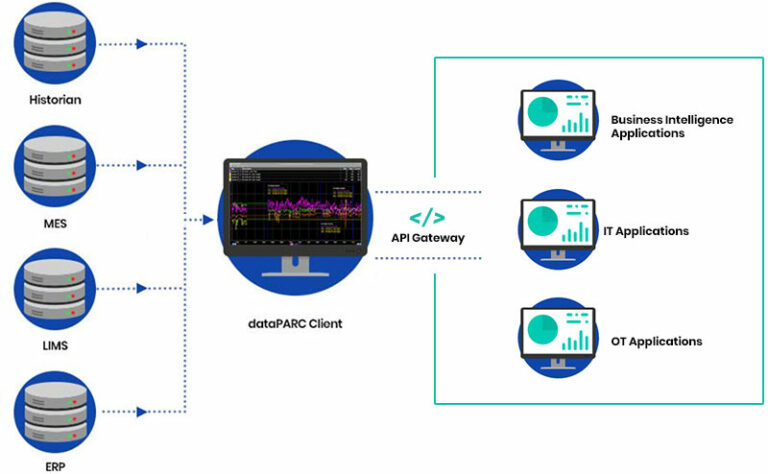

With dataPARC, you can seamlessly integrate and analyze data from multiple sources to drive continuous process improvements.

dataPARC’s solutions offer robust data collection, storage, and visualization capabilities. Monitor production in real-time and analyze historical data to identify trends, troubleshoot issues, and enhance operational efficiency.

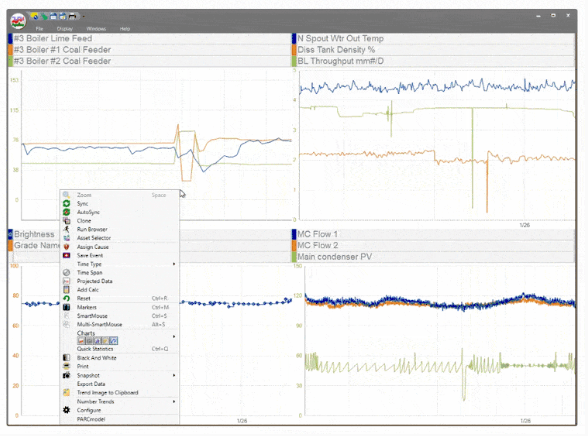

PARCview is a powerful analytics tool designed to enable data-driven decision-making on the plant floor and across your enterprise. With PARCview, you can:

PARCserver is a high-speed process data historian software that ensures maximum data integrity and accessibility. Key features include:

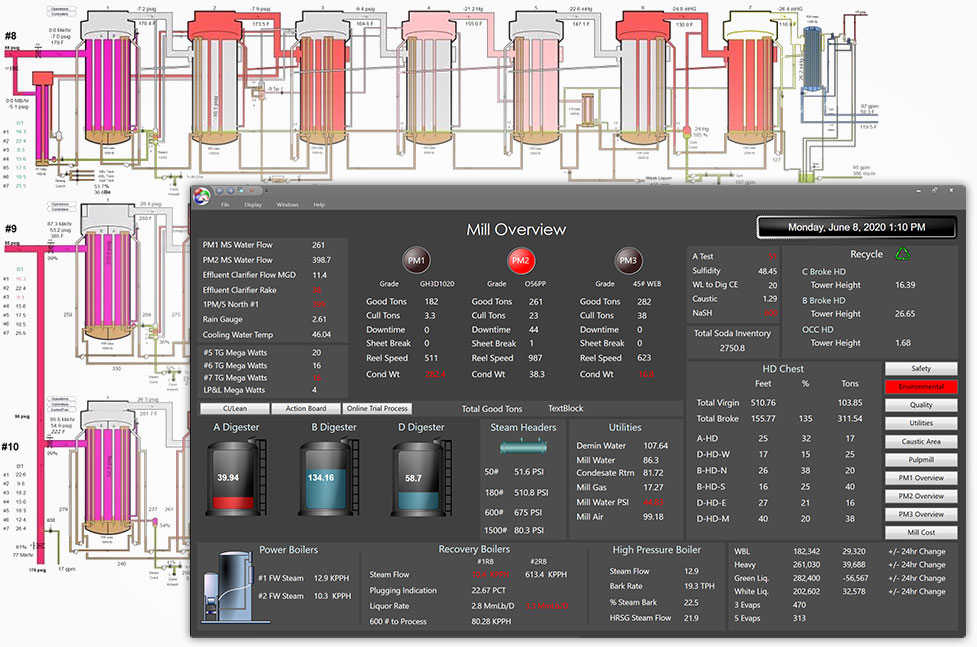

Drive continuous process improvements, quality, and overall efficiency with advanced tools to help you optimize manufacturing processes. With dataPARC’s Manufacturing Process Optimization Software, you can:

Monitor production performance health and gain insights into current operating conditions and process KPIs for enterprise-wide visibility. dataPARC’s Real-Time Production Monitoring Software is a powerful tool that allows you to: