Aveva™ PI System™

Vendor-neutral and purpose-built for industry solution for collecting, enriching, storing, and accessing reliable, real-time operations data.

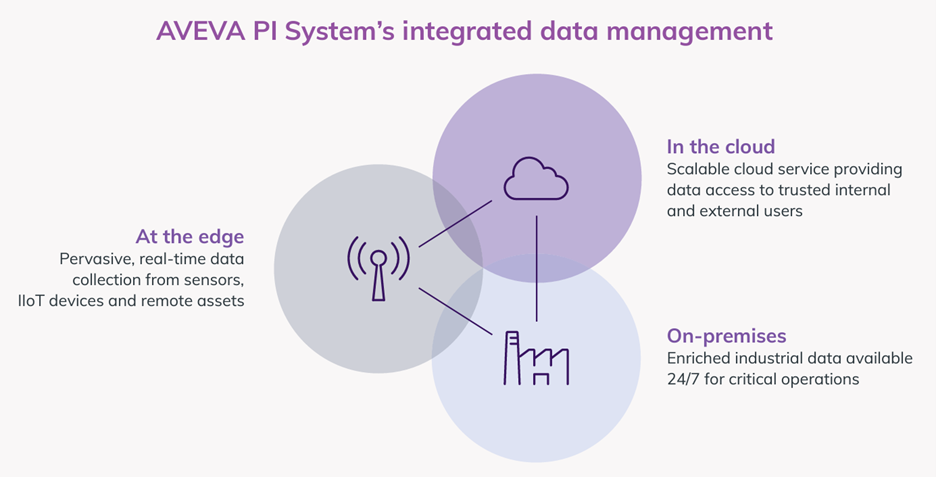

AVEVA PI System is a data management platform that is purpose-built to collect, store, and manage sensor and time-series operations data via our integrated edge, on-premises and cloud products.

Every day, industrial professionals at two-thirds of the Fortune 500 companies rely on the PI System to improve operational performance, protect health and safety, keep the lights on, and make the world run more smoothly.

With just a few clicks and minimal configurations, you can get all your critical operations data anywhere in your operating environment and make it available to engineers, analysts, data scientists, developers, and decision-makers in any location.

PI System for high availability with end-to-end redundancy and immediate failover to support disaster recovery, maintain emergency operations centers, and maximize uptime. You can deploy PI System components in a variety of architectures, including in a DMZ, on virtual machines, and in cloud environments.

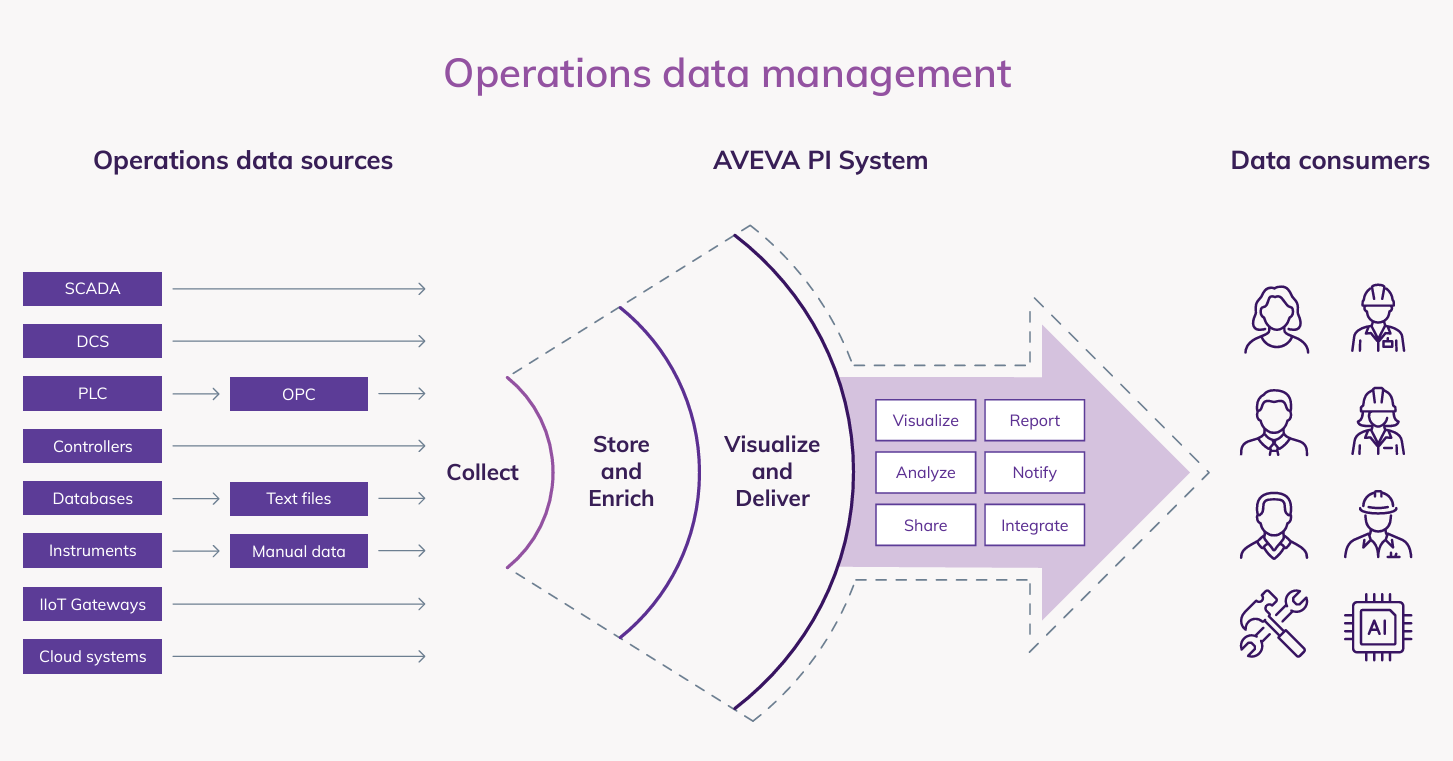

AVEVA PI System pulls data from complex industrial systems such as programmable logic controllers (PLCs), distributed control systems (DCSs), SCADA, instrumentation, laboratory information management systems (LIMS), and others. Legacy equipment is no problem. There’s over 450 native interfaces and 20+ smart connectors across vertical segments that work out-of-the-box to collect data and centralize it in a common data archive.

As a result of digitalization, many industrial companies now have hundreds, or even thousands, of sensor-enabled devices located beyond their on-premises operating facilities. Edge solutions allow you to collect, locally store, and access operations data from sensors and assets outside your primary control network.

Operations data can be used by engineers in different domains and by analysts at the enterprise level. This architecture eliminates data silos and gives everyone access to a single source of truth. New data is seamlessly integrated as it arrives in real time, whether that is once every hour, minute, or fraction of second.

Compute simple averages and unit conversions, as well as more sophisticated calculations like total energy usage or the days of raw material remaining. You can also define key events in your production process to trigger data collection and compare data to similar events. If performance degrades and action is needed, PI System lets you send automatic email notifications to appropriate team members.

With trusted operations data delivered in real time to people, applications, and platforms across your organization, you can unlock new business value and drive efficiency, flexibility, sustainability, and resilience.