If you consider what is necessary to sustain a successful marriage, communication is going to be at or near the top of everyone’s list. If you then consider attributes that most successful people and managers share, communication is again likely going to be at or near the top of this list. It therefore shouldn’t be a surprise to anyone that improving communication in manufacturing is necessary for optimizing and sustaining top performance.

In many ways, communication is at the heart of Digital Transformation. While data integrity, workflow optimization, and decision support are common drivers for investment in Digital Transformation solutions in manufacturing, communication is the secret sauce that removes silos and swim lanes and allows a manufacturing site to outperform its former self.

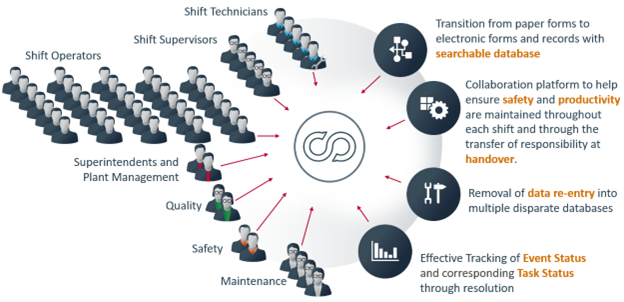

Plant Process Management (PPM) solutions such as Shiftconnector® provide a digitalized framework for Operations, Quality, Safety, Maintenance, Plant Management, and all departments at a manufacturing site to have real-time awareness of underperformance and risk. As its name implies, Shiftconnector is an efficient solution for digitizing shift logs and handover. More importantly, it also serves as the Event Management and Task Management hub for plants of all types in all industries, providing constant awareness of what issues exist and who is responsible for addressing them. This is a key enabler that not only provides for much greater communication, but also a step change in accountability.

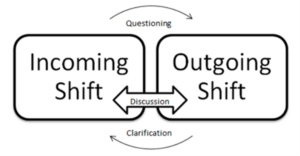

Shiftconnector supports the handover process, an essential activity as incoming Operators and Supervisors must have complete awareness of what risk factors exist as their shift begins. Outgoing Operators and Supervisors share information in a consistent manner, focusing on open Events and the status of the assigned Tasks and Work Orders in place to address these Events. Shiftconnector supports both synchronous and asynchronous handover, helping to ensure that the handover process occurs regardless of circumstances.

Further to this, there are multiple tools layered within Shiftconnector that enable transformed communication, inclusive of the following:

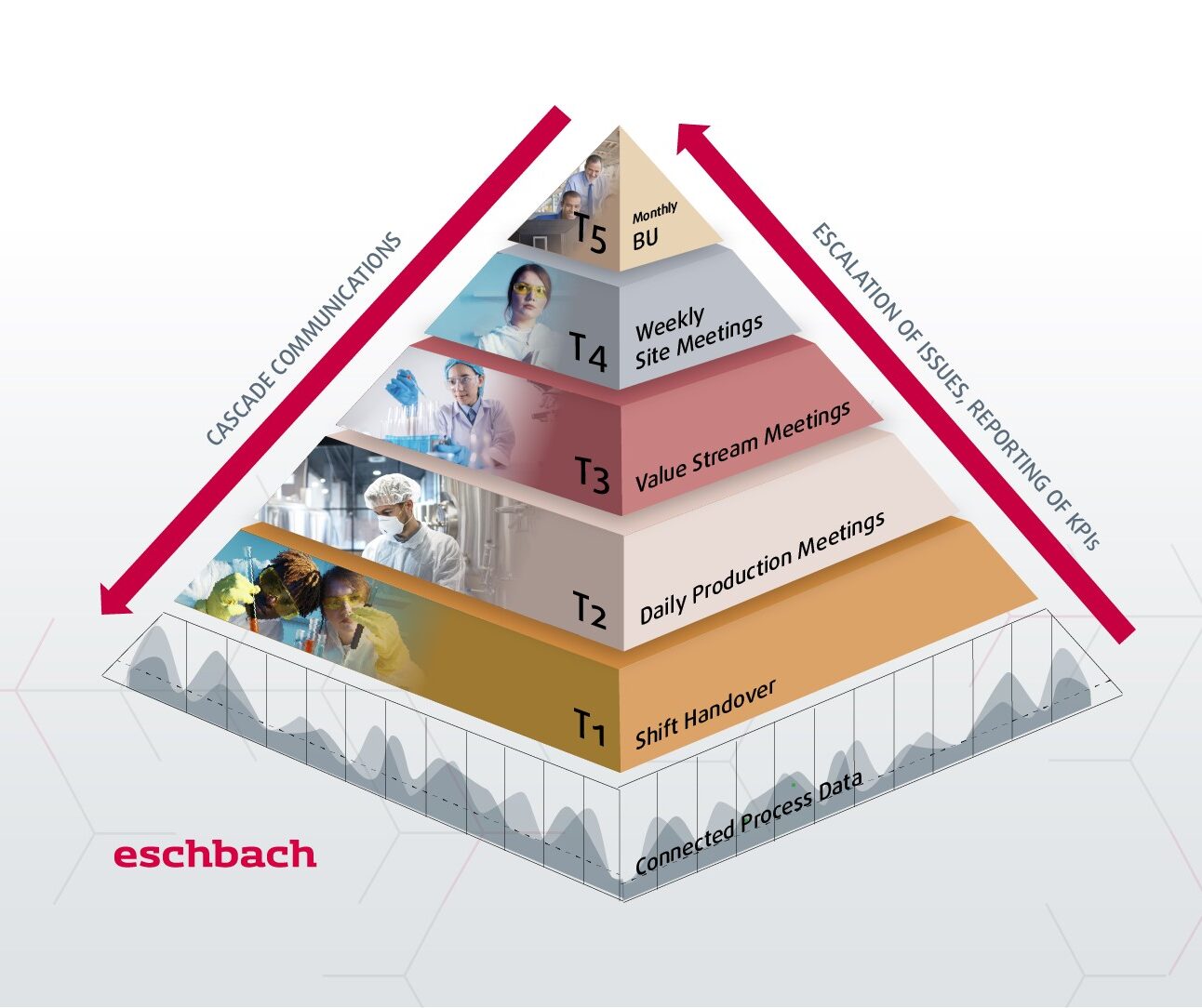

This layering provides a rich environment for increased collaboration and accountability. For example, Morning Meeting provides an opportunity for Supervisors and Operators to review all open high priority Events and Tasks from the night before. 360⁰ Overview provides a snapshot of what’s most important right now for Supervisors and Superintendents. Plant Status provides a quick view to know if a key asset has returned to service or is in the proper state, such as ready to run, running, cleaning, clean, machine set-up, routine maintenance, unplanned maintenance, etc. Tier Collaboration Dashboards provide role specific Key Performance Indicators along with escalation of high priority information (from the bottom up) in a structured manner, and a consistent process to cascade information to the plant floor (from the top down).

Clients universally share the following comments regarding the impact of improved communication enabled by Shiftconnector:

Communication Transformation is indeed foundational for optimized and sustained Manufacturing Performance. Yes, change management will be required as you introduce Shiftconnector to your site(s). That said, we consistently witness rapid adoption, with team members quickly wanting to add use cases of all kinds in support of continuous improvement. Before you know it, the solution is deployed site wide and is central to your culture, and to your long-term success!

Jon Hall

Vice President, Digital Transformation

Adatafy™