Highlights:

A leading fertilizer manufacturing company in the Midwest USA.

The client faced significant operational challenges due to its heavy reliance on a traditional paper-based, manual data collection system for log sheets, handovers, and meter readings.

The process was time-consuming, prone to errors, and made it difficult to analyze historical data and trends.

With numerous operator rounds across various departments like Ammonia, PSL (Storage & Loading), and Utilities, the company struggled with accessing and sharing data, assigning tasks, obtaining required approvals, and ensuring accountability.

The need for a digital transformation was pressing to ensure better organization and data management and to enhance overall productivity.

Recognizing these challenges, the fertilizer company partnered with Adatafy™, a Novaspect trademark, to implement the core Shiftconnector Plant Process Management System and Shiftconnector GO Mobile Rounds App.

Adatafy’s Software Engineering professionals initiated a project to design, configure and implement a comprehensive digital solution tailored to address the customer’s specific goals and functional requirements.

By taking a collaborative approach and gathering input from multiple users including operators, supervisors and superintendents, Adatafy developed a system that would improve each stakeholder’s day-to-day activities, be well-received, and obtain the maximum benefit for the organization.

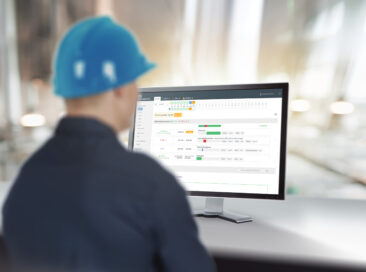

The Shiftconnector deployment included the creation of 10 core application forms and functional requirements, covering critical areas such as:

Also, with the addition of Shiftconnector GO, operators would be enabled to conduct rounds digitally (online or offline) using mobile data capture instead of relying on paper.

As the project progressed, the customer reviewed, tested and provided feedback in a development environment. Once approved, Adatafy conducted training sessions for administrators and key users to manage and utilize the system effectively upon launch.

The Shiftconnector implementation marked a significant shift from a paper-based environment to an easy-to-use, all-in-one digital platform, resulting in improved data accessibility and operational efficiency.

The client reports their users are highly satisfied by the convenience of having a one-stop shop with more detailed information and a vastly improved handover experience.

Additionally, the successful initial deployment of Shiftconnector will lay the groundwork for future advancements. The company will be able to better leverage their data across other platforms to make informed decisions and maintain a competitive advantage.

Download the Case Study

How can you digitize/automate operator rounds?

Digital operator rounds improves data accuracy, enhances operational efficiency, facilitates better data analysis, and reduces the time and effort required for manual data entry. It also helps in maintaining compliance and improving overall productivity. Automating operator rounds involves several key steps and the use of specialized software.