Highlights:

A global manufacturer of lubricants and soaps used in the medical industry, with operations at a Midwest USA site.

The client faced significant challenges in managing their bulk batch production processes. They were using paper batches in Excel, printing them off, writing by hand, and then going through a sign-off process before saving them in a binder. This manual workflow made it difficult to access records easily.

Another major issue was the risk of accidentally dispensing the wrong product, which happened a couple of times a year, resulting in increased costs due to the loss of raw materials, product, and time.

Additionally, the company needed to comply with CFR 21 Part 11 regulations for electronic records and signatures, which their existing framework could not support.

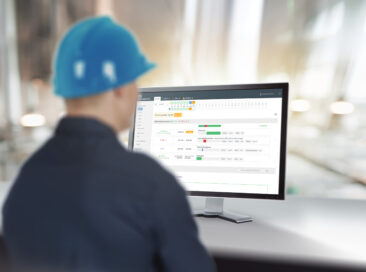

The client chose TrakSYS, a best-in-class manufacturing operations management system, to address their challenges. Software engineers at Adatafy™, a Novaspect trademark, configured the TrakSYS system to manage bulk batch production, recipe management, and material traceability.

System features included:

The successful implementation of TrakSYS transformed the client’s manufacturing operations and led to significant improvements:

The project demonstrated the system’s ability to enhance efficiency, compliance, and traceability, setting the stage for future expansions and continued improvements. The client is now better equipped to meet industry standards and regulatory requirements, ensuring high-quality production and operational excellence.

Download the Case Study

What are electronic/digital work instructions?

Electronic or digital work instructions are modern, paperless versions of traditional work instructions and standard operating procedures (SOPs). Digital work instructions are available on various devices, making it easy for workers to access instructions anytime, anywhere. Information is used for training and transferring expert knowledge to employees and can be updated in real-time to reflect current procedures. They often include multimedia elements like images, videos, and interactive components to enhance understanding. Data can synchronize with other digital systems, such as IoT devices or enterprise resource planning (ERP) systems, to provide greater flexibility across platforms.

What is CFR 21 Part 11 regulations for electronic records and signatures?

CFR 21 Part 11 is a set of regulations established by the FDA to ensure that electronic records and electronic signatures are trustworthy, reliable, and equivalent to paper records and handwritten signatures. Here are some key points:

These regulations help ensure that electronic records and signatures are as reliable as their paper counterparts, supporting the integrity of data in critical industries.

How can you improve traceability in bulk batch production?

Improving traceability in bulk batch production involves several key strategies and technologies. Here are some effective ways to enhance traceability:

By implementing these strategies, you can significantly improve traceability in bulk batch production, leading to better quality control, regulatory compliance, and overall operational efficiency.