A Seamless Shift: Manufacturer Migrates Data Historian and Process Book Displays from AVEVA PI System to Aspen InfoPlus.21® (IP.21)

A leading, global manufacturer and supplier to the food and beverage industry.

The customer operates multiple manufacturing facilities and had planned to update the technology at its Midwest plant to adhere to the same standards and procedures already implemented at the company’s other sites worldwide.

The Midwest facility was using the AVEVA (formerly OSIsoft) PI System and Aspen InfoPlus.21® (IP.21) data historians in tandem for several years, which was redundant and increasingly difficult to manage, so they planned to migrate the data into the IP.21 platform to align with corporate initiatives.

Additionally, the site’s legacy thick client process control visualization environment, AVEVA PI ProcessBook, was scheduled to reach end-of-life by December 31, 2024, so the functionality needed to be converted before then.

Although the customer had an in-house IP.21 administrator, they didn’t have the time or resources to dedicate to the project’s scope and to ensure all the history, tags, calculations, displays and integrations carried over and functioned as expected on the new platform.

Because of the longstanding relationship and positive track record on previous deployments, the customer entrusted Adatafy™, a Novaspect trademark and Implementation Service Provider for AspenTech solutions, to achieve the migration.

Adatafy’s Solutions Architect and AVEVA PI subject matter expert initiated the project and worked directly with the customer to assess the scenario and to define the steps needed to successfully complete the move to IP.21.

Using the AspenTech PI to IP.21 migration utility, Adatafy:

Adatafy also:

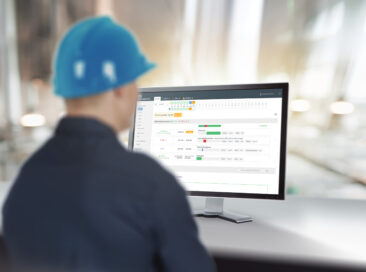

In a few short months, the team at Adatafy successfully completed the migration of the customer’s past 7 years of PI System historian data and ProcessBook Displays into its existing IP.21 and A1PE environment.

This was an intricate project, and the level of complexity meant it required intimate knowledge of multiple Distributed Control Systems and software solutions that the Adatafy team was well equipped to manage.

The result was a marked improvement in data management for the Midwest plant through the elimination of redundant systems, improved data integrity, and reduced maintenance challenges.

The update empowers the customer with better insights on historical data and key performance indicators, enabling quicker and more informed decision-making, and the ability to quickly troubleshoot potential issues.

Ultimately, the plant not only achieved its goal of aligning with corporate technological standards, but also unlocked and took ownership of its historian data, significantly boosting their competitive edge in the global food and beverage industry.

Download the Case Study